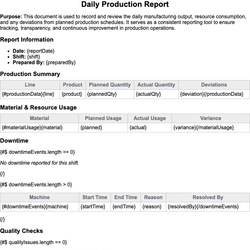

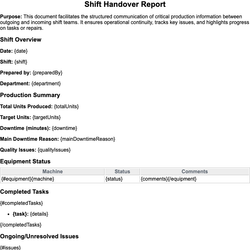

Manufacturing & Quality

Manufacturing and production templates including work orders, quality checklists, inventory lists, and safety reports.

56 Templates

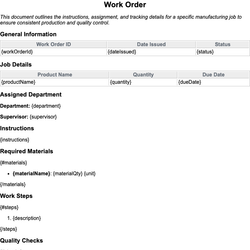

DocumentDOCX

DocumentDOCX

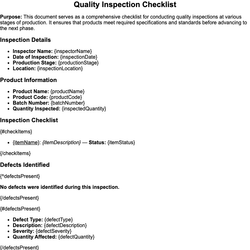

DocumentDOCX

DocumentDOCX

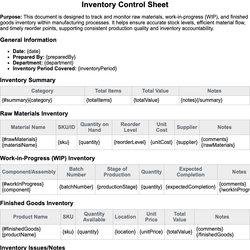

DocumentDOCX

DocumentDOCX

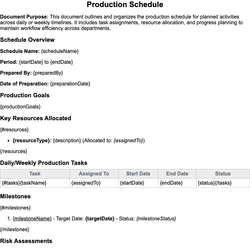

DocumentDOCX

DocumentDOCX

DocumentDOCX

DocumentDOCX

DocumentDOCX

DocumentDOCX

DocumentDOCX

DocumentDOCX

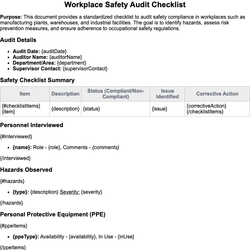

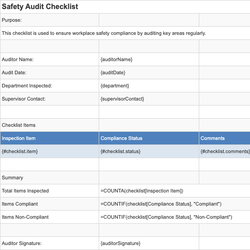

Workplace Safety Audit Checklist

DocumentDOCX

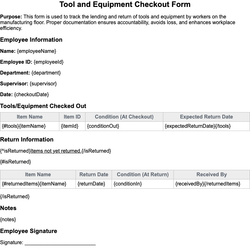

Tool and Equipment Checkout Form

DocumentDOCX

DocumentDOCX

DocumentDOCX

DocumentDOCX

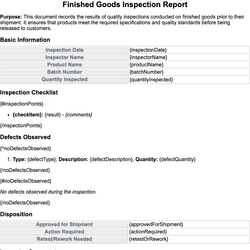

Finished Goods Inspection Report

DocumentDOCX

DocumentDOCX

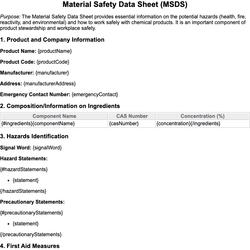

Material Safety Data Sheet (MSDS)

DocumentDOCX

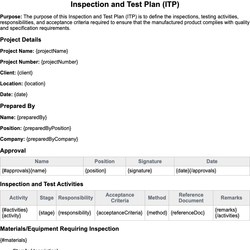

Inspection and Test Plan (ITP)

DocumentDOCX

DocumentDOCX

DocumentDOCX

DocumentDOCX

Supplier Non-Conformance Report

DocumentDOCX

DocumentDOCX

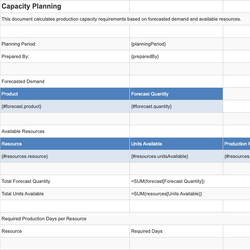

Manufacturing Capacity Planning

DocumentDOCX

DocumentDOCX

DocumentDOCX

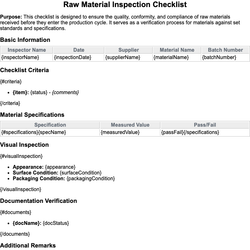

Raw Material Inspection Checklist

DocumentDOCX

DocumentDOCX

DocumentDOCX

Environmental Compliance Report

DocumentDOCX

DocumentDOCX

DocumentDOCX

DocumentDOCX

DocumentDOCX

DocumentDOCX

DocumentDOCX

DocumentDOCX

DocumentDOCX

DocumentDOCX

DocumentDOCX

DocumentDOCX

SpreadsheetXLSX

SpreadsheetXLSX

SpreadsheetXLSX

SpreadsheetXLSX

SpreadsheetXLSX

SpreadsheetXLSX

SpreadsheetXLSX

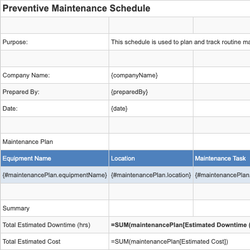

Preventive Maintenance Schedule

SpreadsheetXLSX

SpreadsheetXLSX

SpreadsheetXLSX